At Hungaria Down Ltd., we are committed to using the latest technologies to enchance the quality of our products. One of these technologies is called "Fresh Washed Down".

What is Fresh Washed Down?

The Fresh Washed Down branded feather and down products, were processed and washed immidiately after it is collected from the animals, on the spot at the slaughterhouses.

To achieve this, a special washing and optional drying line is installed at the slaughterhouses, where the down is sourced from.

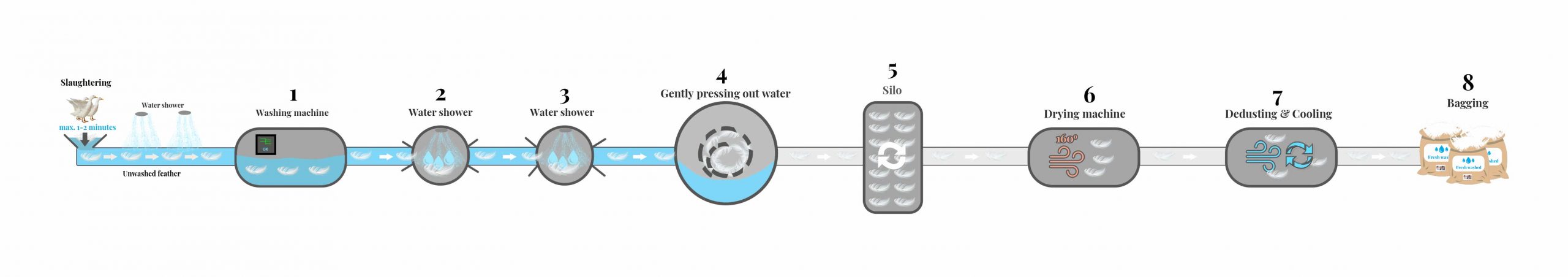

The process

0.

The plumage is removed from the animals, and transported to the washing line. Within maximum 2 minutes of the feather collection, the Fresh Washed Down process starts with immidiate clean water shower, where the largest dirt particles are removed.

1.

The feather and down is then transported to a washing machine, where a special washing program deeply cleans the product for 30-60 minutes, removing any small unwanted particles.

2, 3.

Two more cycles of clear water shower follows the deep cleaning.

4.

A special machine presses out the majority of the water from the feather and down. It is very important to do this process gently, because otherwise the down cluster may be damaged.

5, 6.

The product then is stored in silos, and dried on high temperature, to ensure complete cleanliness and hygene.

7.

The product is put into a fiber / dust removing machine, to remove the smallest amount of dust, and to cool it down before preparing for shipping.

8.

Within just a couple of hours, the raw feather and down is converted to Fresh Washed Down, is baled and shipped to our factory.

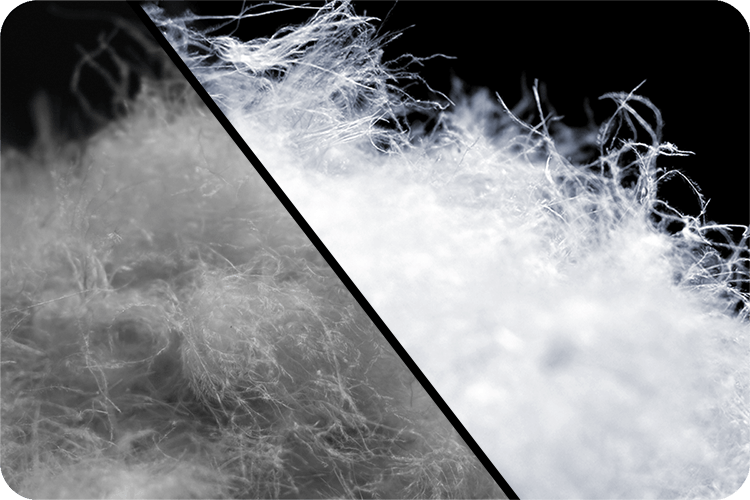

The outcome

What is the purpose of these steps, and quick washing?

Two major advantages compared to regularly washed down.

- No odour, only clean and beautiful down.

- Fiberless, only large down clusters remain.

Recovery power

Duvets and pillows made with Fresh Washed Down have superior recovery power meaning they keep their original volume for longer.